Avoid the Mistakes That Lead to Callbacks

Even seasoned contractors slip up on lighting jobs. And when they do, it’s usually one of these seven.

We put this list together to help you spot problems before they happen—so you can support your contractors, avoid service calls, and keep systems running strong.

Here’s what to watch for:

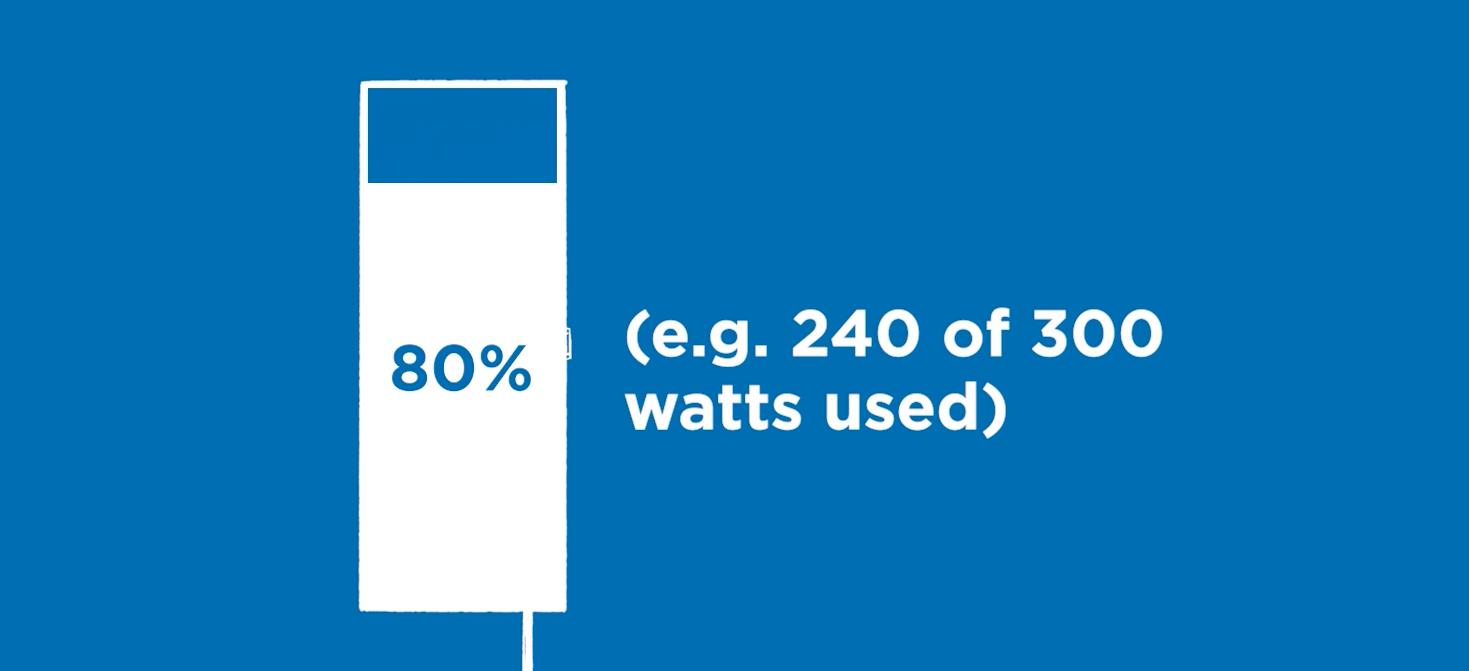

MISTAKE 1:

Overloading the Transformer

Stay under 80% of the transformer's rated load—every time.

MISTAKE 2:

Skipping Voltage Tests

If you’re not testing at the fixture, you’re guessing. Use a multimeter to confirm voltage is in range.

MISTAKE 3:

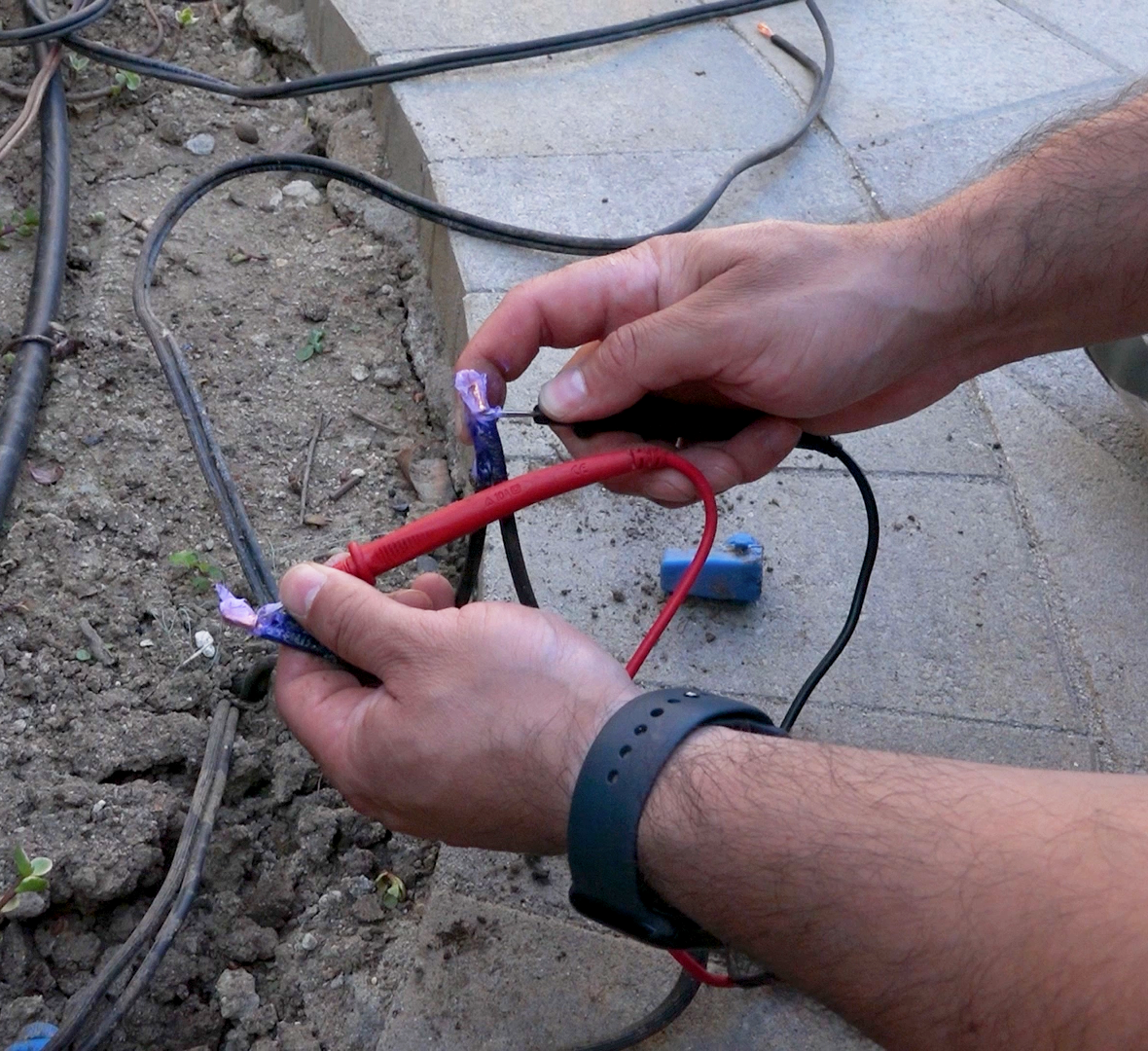

Bad Connections

Open wire nuts and exposed copper lead to corrosion and failure. Use waterproof connectors like the ALOC.

MISTAKE 4:

Undersized Wire

Long runs need thicker wires.

Here are some rules of thumb for the most common wire gauges:

- #16-2 is good for up to 96 watts

- #12-2 is good for up to 182 watts

- #10-2 is good for up to 364 watts

Know your distances and load before pulling any cable.

MISTAKE 5:

Poor Fixture Placement

Lighting is only effective if it’s seen. Don’t bury path lights or aim uplights into space.

MISTAKE 6:

No Future-proofing

Leave slack, allow headroom on the transformer, and plan for growth.

MISTAKE 7:

Cheap Fixtures

They don’t last, and they don’t help your reputation. Stick with solid brass that’s built to take a beating.

Bottom line:

The best installs are the ones that don't come back. Share these with your team or your contractors—and let the lighting do the talking.

Use this form to sign up for our newsletter. If you need technical support, please contact our

Use this form to sign up for our newsletter. If you need technical support, please contact our